We live in a world where technology is changing so fast, it’s mind boggling. I remember the first day I saw a fax machine work and thought, “wait, you’re telling me that a piece of paper goes through the telephone lines and out the other side?” Queue the mind explosion.

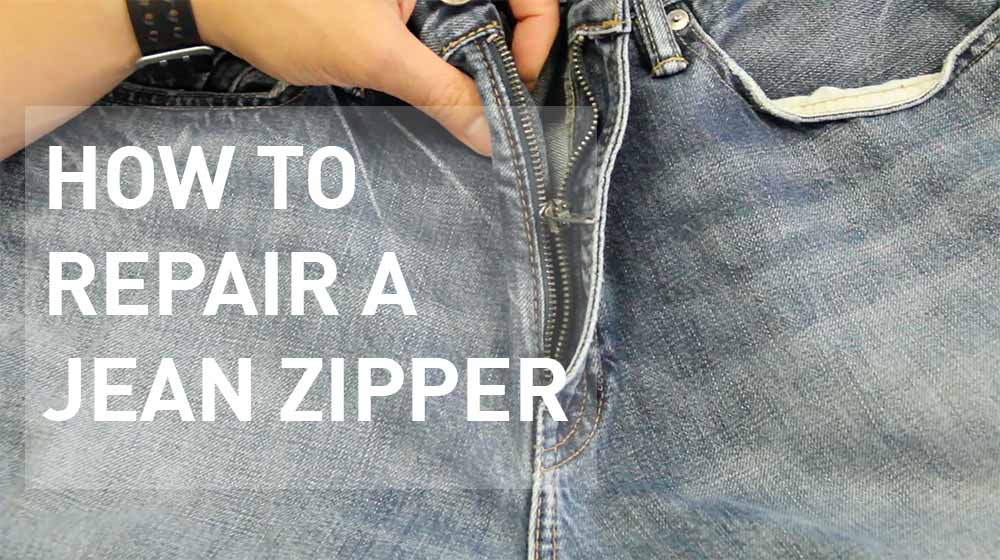

With all of the change, zippers have been pretty steadfast. There have been some minor changes, but as a whole, zippers have been the closure of choice for decades. Along with zippers, denim has also been a mainstay in the fashion world. A question that we get quite often is, “what makes a denim zipper for denim?” Read on to find out more.

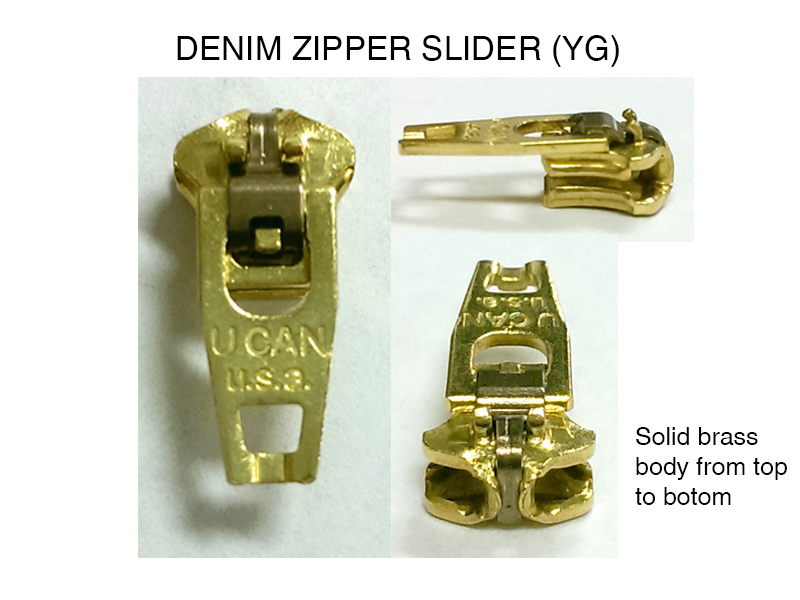

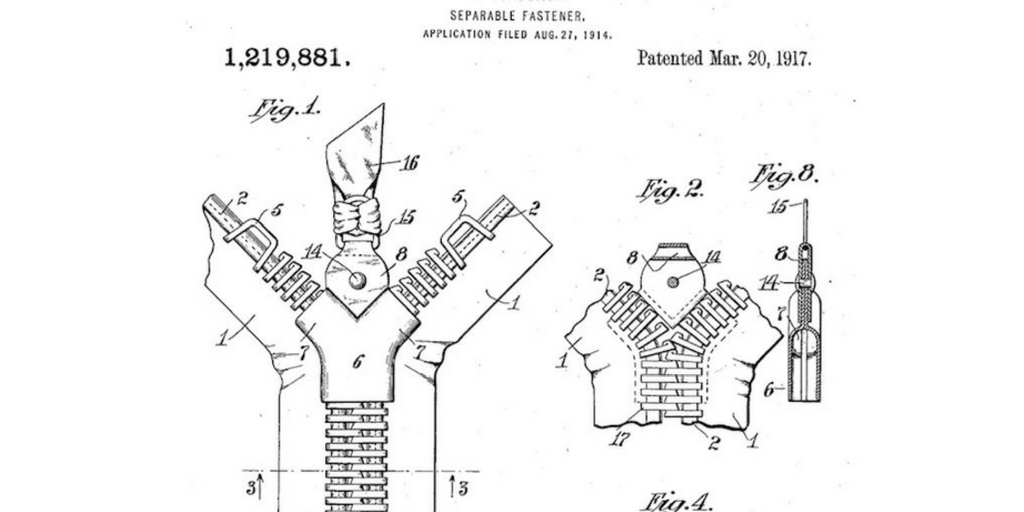

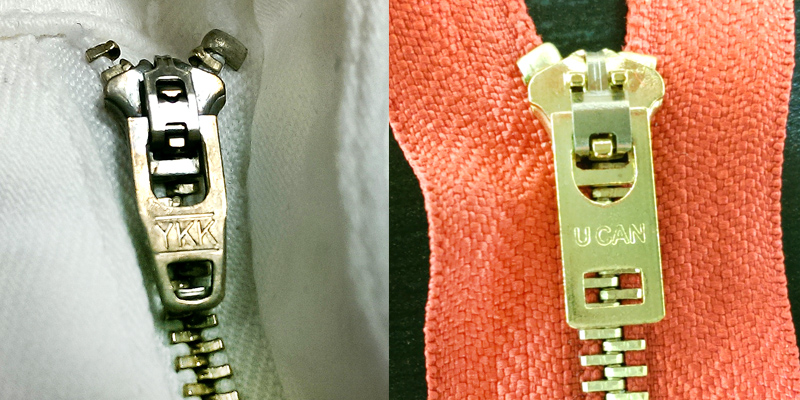

Truly, denim zippers or zippers that are made for denim are virtually the same zippers that we make for other garments. Most often, the teeth are made from brass. For all of the torture that denim goes through, brass teeth are pretty good at holding up to the abuse. The slider is the biggest difference. We call the denim slider a “YG” slider. The YG sliders are a flat lock slider and the slider body is made from one solid piece of brass. The pull has a bit of tension on it to keep it flat and not freely dangle. If you compare the YG slider to other zinc die cast sliders, you’ll see that the die cast slider has more moving parts, whereas the YG does not. This solid brass construction is intended to withstand typical denim washes and also ensure years of use. The most common gauge size for the fly of jeans is a #4, however #5’s may be used when the design requires a larger teeth look.

In some instances, apparel brands will use a die cast zipper. In my opinion, it’s an oversight on long term quality. In our experience, the die cast slider will fail much sooner than a denim zipper, or YG slider. Especially if the denim will be going through serious industrial washes to achieve a particular look.

Whether you’re a designer, product developer, or trim buyer, you are now armed with a bit more zipper knowledge to make better choices for your apparel pieces.

Leave a Reply