Here is Part 2 of How Zippers Are Made. In Part 2 – Adding Teeth to the Zipper Tape, we show you how the teeth are actually put on the tape.

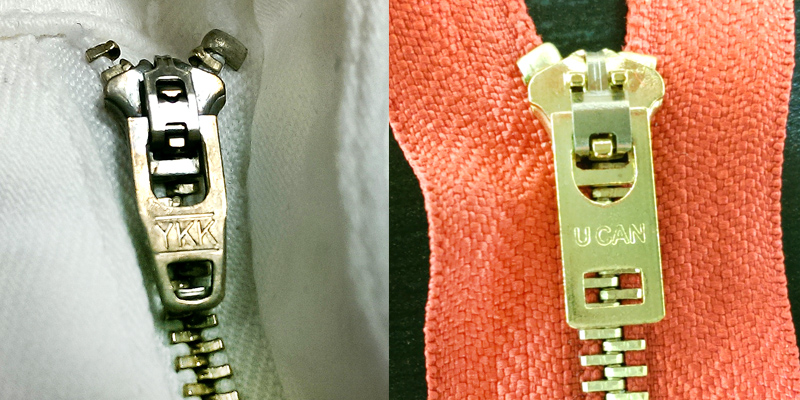

After dyeing the zipper tape, it goes over to production for the teeth to be added. In the metal process, we start with brass wire. All of our metal wire starts with brass as to stay within EU requirements for nickel-free products. The teeth are punched on with machines at a rate of 2,200 teeth per minute.

After the teeth are on the tape, the zipper sides need to be joined. Following the joining process, the zippers are then sent to “gap”. The gapping process is to set up the length the customer has ordered. There is a 2 inch gap, then the length of zipper teeth that is the length specified. You can see that the tape extensions (the tape that extends beyond the teeth) have no bearing on the total length of the zipper. If you want to know how to measure a zipper correctly, you can read more here.

After the length is set up by the process of gapping, then it moves on to the slider machine to mount the sliders, top stops, then cutting. Stay tuned for the Part 3 – Painting and Mounting Sliders

Leave a Reply