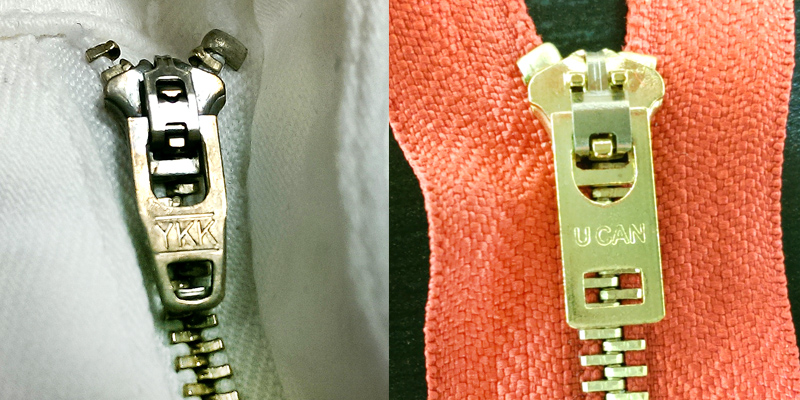

With any design that we see, there are unique traits and qualities a designer will put in to have it stand out or be “something different.” We see this with how trim is applied to a dress. Or with the use of different patterns, or even mixing and matching unique textiles. All of these unique traits that designers painstakingly craft are various ways to brand the final product. As we’ve heard before, “the devil is in the details” and that’s no different for zippers.

When a product developer or designer come to see our zippers, one of the questions that we get is, “can you make a custom zipper pull?” In this post, we’re going to walk you through our process of designing and producing custom zipper pulls.

The answer to the question above, “can you make a custom zipper pull?” is an emphatic, yes. In fact, we would rather have you work with us, rather than find your source separately. The reason is that there are certain aspects of the zipper that you’ll want to match, and the zipper pull is no different. I’ll share details about that later.

We should start off by clearly stating that any custom zipper pull project has a 5,000 piece minimum, per design, per finish (if it’s for metal zippers). To begin the process of producing custom zipper pulls, we need as much information as possible about what you want to create. We’ve had designers and product developers come in and say, “can we just create something like this?” as they’re pointing to something that inspired them in a magazine. Yes, we can do something like that, but we will STILL need as much information for that design that we can get.

We need to know:

- Desired length

- Desired width

- Desired thickness

- Will the logo be embossed or depressed?

- Desired finish

- What zipper will be applied to the product? Metal, nylon coil, plastic molded, etc.?

This detailed information will help us generate a more exact quote for you to use in your decision-making process. These details will be submitted in an Adobe Illustrator or Photoshop file.

Once all of the specifications are confirmed, we then move into CAD drawings. Our CAD drawings will give you an idea, in 2-D, how the pull will come out. CAD drawings take about one week to produce. Our CAD drawings are paramount because this is where you will make a decision on whether or not you want to move forward with the production of the mold.

If the CAD drawings are approved, we will collect the mold charge fees. There is a great range in mold costs because of the different designs people come up with. As a general rule, we have seen prices range from $400.00 – $600.00 per mold. This all depends on the detail of the artwork. Production of the custom zipper mold and pressing out first samples takes about two weeks.

One thing to note is that when the first samples are received for approval, very little can be changed at this point. We can make some small tweaks if something wasn’t depressed enough or a letter isn’t very clear. But to make broad swaths of changes will most likely result in having to create a new mold.

Also, this is where it is critical to note that if you were ordering zippers from us, it would be in your best interest to also produce custom zipper pulls with us. Here’s why. We had a product developer come to us and ask if we produce custom zipper pulls. We told her that we do and gave her all of the information requested. She didn’t want to purchase zippers from us because she believed that she was getting a better price by individually sourcing the trim. After all of the communication between her and us, when the pulls came back, they didn’t fit the slider body that they were intended to go on. There she was, with 5,000 custom pulls and none of them fit. Now, I’m not saying that we’re the only zipper factory in the nation that can make both custom pulls and zippers, but wherever you decide to source your parts, make sure that you measure everything.

Finally, after the molds have been reviewed, full production will begin. The cost of the new custom zipper pull will range, again depending on the detail of the artwork and size of your pull. In our experience, we have had the cost of pulls range from $0.35 – $6.50 per piece. The entire process from beginning to end will run about 4-6 weeks.

So here’s a summary: Custom zipper pulls minimum: 5,000 pcs per design, per finish Customer to provide specifications CAD drawings provided based on customer spec. (1 week) Approved CAD drawings, begin mold production (2 weeks) First samples in hand and approved, start total production (2-3 weeks)

Whether you work with us or another company, the idea will be the same. This will give you a idea of what it takes to design and produce custom zipper pulls.

Leave a Reply