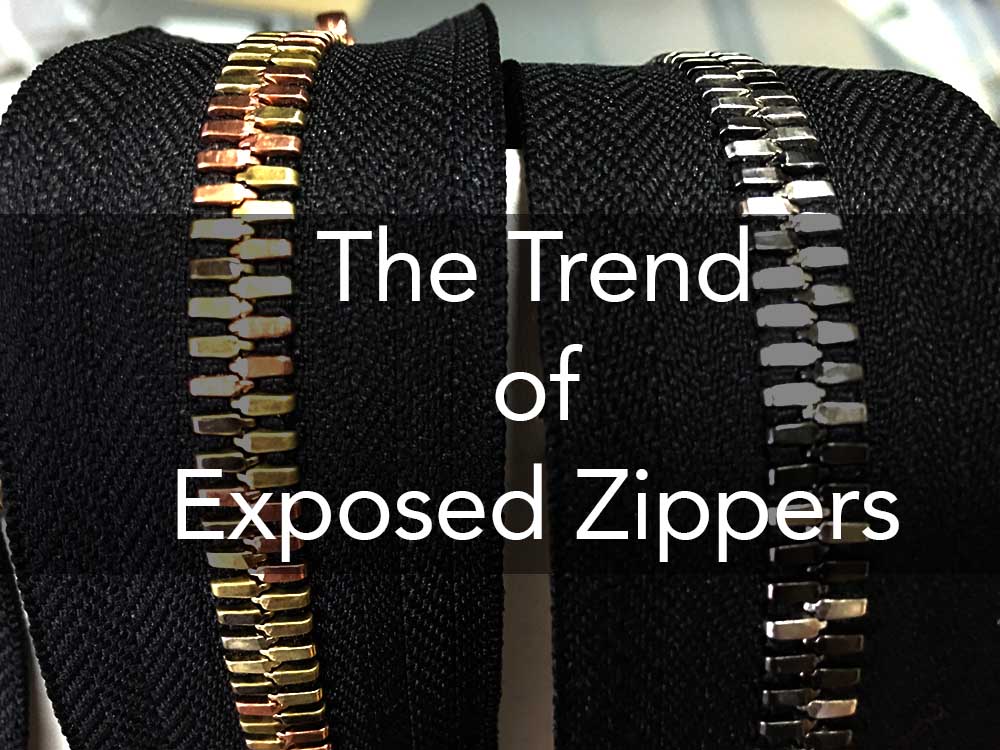

When you’re designing pieces that need zippers, it’s a good idea to get to know the zipper terms that are used in the industry. It not only makes it easier when working with zipper companies, it will give you some serious zipper street cred.

Gauge Size: When the term “gauge size” or “zipper size” comes up, it’s referring to the size of the teeth. Depending on the design and final application or use of the piece will drive the gauge size of the zipper used.

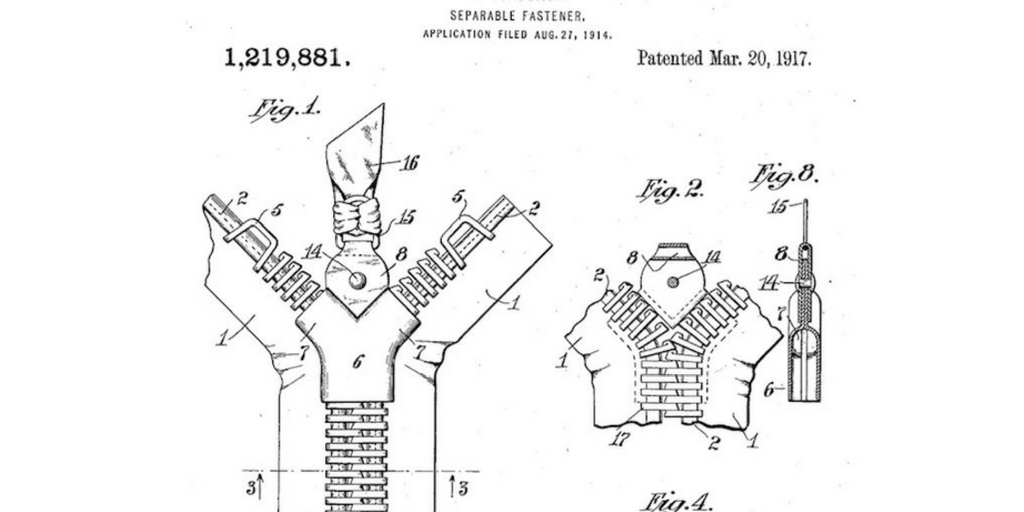

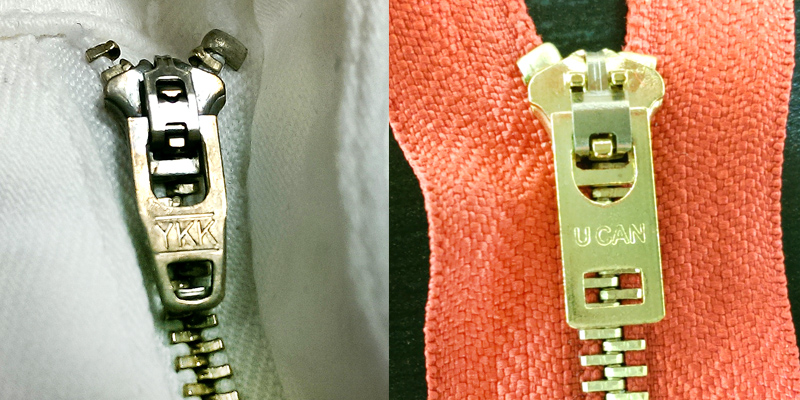

Slider: AKA – zipper car, AKA – pully thingy. The slider is the actual part that opens and closes the zipper. Some people mistake the slider as the zipper, but in fact the zipper refers to the entire zipper; teeth, slider, and stops.

Stops (Top & Bottom): AKA – stoppers. The top and bottom stops of the zipper are used to stop the slider from coming off the zipper.

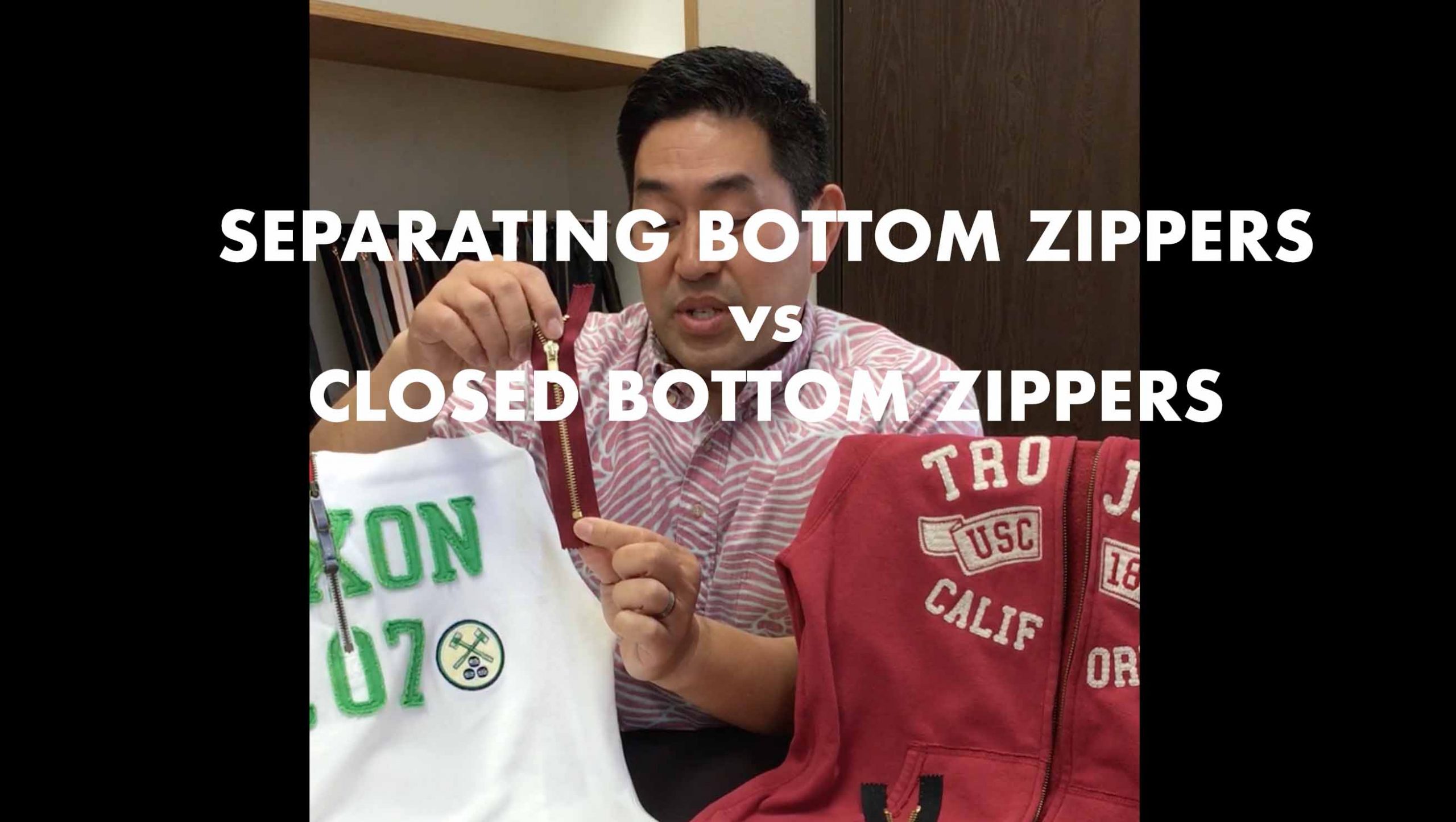

Separating Bottom: AKA – open end, AKA – separating end, AKA – separating zipper. A separating zipper is the most common zipper used in a jacket or any other function where one side of the zipper must completely separate from the other.

Closed Bottom: AKA – closed end. A closed bottom zipper is most commonly used on pants or any application where the zipper just opens one portion of the design. This zipper will open, but will NOT separate like a Separating Bottom zipper.

Long Chain: AKA – zippers on a roll, AKA – zippers by the yard, AKA – continuous chain. Long chain is the zipper tape and teeth on a roll of measurement the client specifies. Most handbag sewing contractors purchase zippers in long chain form so they can cut any length they need and assemble the sliders and stops to meet the design needs.

Two Way Separating Zipper: AKA – double zipper. This zipper is a separating bottom zipper (see above) with two sliders that work in opposing directions. The historical use of this zipper was for long coats. When the wearer would sit down, they would zip up the bottom slider to give them leg room. Today, with shorter length jackets, there’s really no reason to have a two way separating zipper. It’s done more as a traditional nod.

Auto Lock Slider: This slider has a locking pin inside the slider body. This pin keeps the slider from freely moving on the zipper chain. An auto lock slider is most common on apparel, notably on the center front zipper on outerwear or back center of dresses.

Non Lock Sliders: This slider has no locking mechanism inside the slider body. This slider is most commonly used on handbags because without the locking mechanism, the slider can move freely with a smooth zipping action.

There you have it. 9 zipper terms you should know to help you along the, sometimes confusing, zipper path.

Leave a Reply